Benefits of Bucket Elevators for bulk materials handling

That’s where bucket elevators come in. In this guide, we’ll explore the benefits of bucket elevators for bulk materials handling, why industries like food processing, agriculture, mining, and packaging rely on them, and how choosing the right elevator can improve efficiency, safety, and ROI.

- Difficulty moving materials vertically to storage silos or hoppers.

- Spillage and product losses during transport.

- Increased manual labor costs and safety hazards.

- Inefficient systems leading to production bottlenecks.

✅ Why Bucket Elevators Are the Solution

Bucket elevators are designed to lift bulk materials vertically, making them the most efficient system for height-based transfer. Unlike conventional conveyors, they save space, reduce manual labor, and handle high volumes of material with minimal spillage.

Whether you’re in food processing, stone crushing, chemical industries, or warehousing, bucket elevators ensure faster, cleaner, and safer handling of bulk goods.

💡 Top Benefits of Bucket Elevators

1.High Lifting Capacity

Bucket elevators can handle large volumes of materials continuously, making them ideal for industries that demand bulk throughput.

2. Space-Saving Vertical Design

Instead of long horizontal conveyors that take up floor space, bucket elevators move materials vertically, freeing up valuable real estate in your plant.

3. Versatility in Materials

From fine powders like flour to coarse aggregates like gravel, bucket elevators accommodate different material types, densities, and temperatures.

4. Continuous & Efficient Operation

They run smoothly with minimal stoppages, ensuring consistent material flow to storage silos, hoppers, or production units.

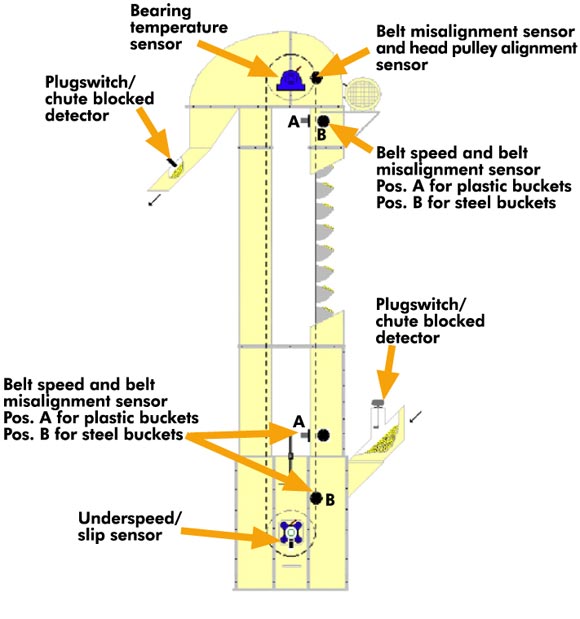

5. Low Maintenance & Safety Features

Modern designs, such as those from Neo Conveyors, include durable chains, wear-resistant buckets, and safety switches to ensure reliability and worker protection.

6. Long-Term Cost Savings

Though the initial investment may be higher, bucket elevators cut labor costs, reduce spillage, and minimize downtime, leading to long-term savings.

🏗️ How to Choose the Right Bucket Elevator

When selecting a bucket elevator, consider: Material Type & Properties (abrasive, sticky, hot, etc.) Capacity Requirements (tons per hour) Height & Discharge Point Environment & Safety Needs

👉 Pro Tip: Always choose a manufacturer that offers customized bucket elevators to suit your material and plant requirements. Companies like Neo Conveyors specialize in bespoke material handling systems that ensure efficiency and safety.

🔑 Conclusion

- Bucket

elevators are a game-changer in bulk materials handling, offering efficiency, safety, and long-term cost savings. By investing in the right system, you can reduce manual handling, minimize spillage, and boost overall productivity.

- To explore custom bucket elevator solutions tailored to your plant,