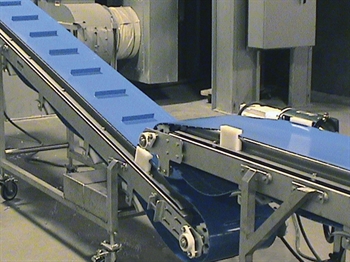

Conveyors are electro-mechanical devices that need regular lubrication and planned observation. If your conveyor stops, your business automatically comes to a standstill. There are some simple fixtures, that you can attempt before calling for repair. It is better to know some tips on maintenance of conveyors, which will keep your belt conveyor running longer.

If your conveyor suddenly stops and turns off on its own, it is a possibility that someone has intentionally or accidentally, hit the emergency stop switch causing the conveyor to close down. Resuming the emergency stop control should revive the conveyor belt. This is an easy fix with minimal downtime.

It should be ensured that the sensors are regularly cleaned and wiped, in order to help the conveying machines to sense where the packages are. Following this practice can avoid this problem of conveying in the future.

The frequent breakdown is generally caused due to overloading of belt conveyors. So, it is vital to know, how heavy a load the conveying machine can handle because the conveyors do have a particular load capacity. However, constantly overloading the conveyor is indeed a recipe for poor performance.

It is really vital to ensure that always belt alignment and its positioning is checked beforehand. Also, wear and tear of the belt should be checked in routine. Employees should be educated about conveyor maintenance, so that, they are able to fix simple things and add to an increase in production. Consider ergonomic workstation, as a way, to keep workers injury-free. Implementing a more comfortable work area gives rise to production.

To know more about conveyors, belt and conveyor systems, log on to http://www.bulkmaterialshandling.in