conveyor pulley manufacturer Manufacturer in India

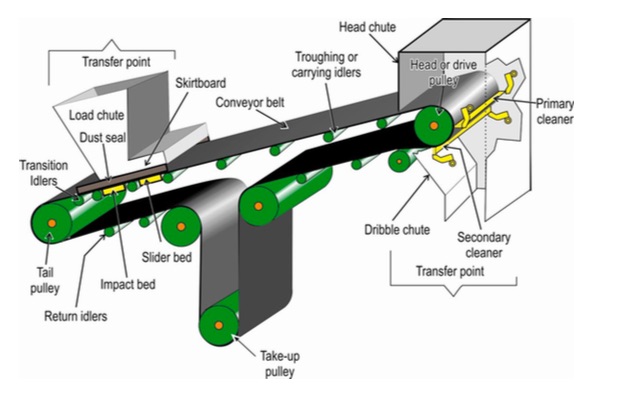

Neo Conveyors, conveyor pulley manufacturer since 2007. A conveyor will consistently comprise of at least two pulleys, head pulley, and tail pulley, with extra pulleys utilized relying upon the design. Standard-obligation pulleys are typically satisfactory for basic applications, however, mine-obligation and designed pulleys are additionally accessible where hardcore pulleys are required.

Types of pulley

- Drive Pulleys

The head pulley or Drive pulley is situated at the discharge point of the conveyor. It as a rule drives the conveyor and regularly has a bigger diameter than different pulleys. For better traction, the head pulley is typically lagged with rubber or ceramic lagging.

- Tail Pulleys

The tail pulley is situated at the stacking end of the belt. It accompanies either a level face or a slatted profile (wing pulley), which cleans the belt by permitting the material to fall between the help individuals.

- Snub Pulleys

A snub pulley increases the wrap angle and improves the traction of the drive pulley.

- Bend Pulleys

Bend pulley used to support vertical weight takeup and changing the direction of the belt.

- Take-up pulley

A take-up pulley is used where we consider vertical weight takeup. Take-up pulley used to give proper tension of the belt and Its position is adjustable.