Do You Know, Why the Bucket Elevator Throw Back Or Return Material in Excess

Learn the main causes of material throwback in bucket elevators, how to fix them, and prevent performance loss. Expert tips from Neo Conveyors.

Introduction: The Hidden Problem in Bucket Elevators

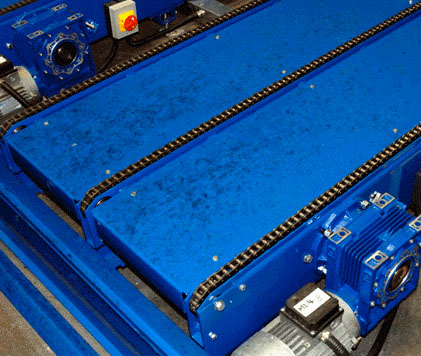

A bucket elevator is one of the most reliable machines for vertical material handling in industries like cement, food processing, and grain storage. But sometimes, operators notice an excessive throwback or return of material — reducing efficiency and causing spillage.

Understanding why this happens is key to keeping your equipment running smoothly.

Common Reasons for Throwback in Bucket Elevators

- Improper Bucket Speed

the speed is too high or too low, material may not discharge properly.

- Incorrect Discharge Timing

Buckets releasing material before reaching the discharge point cause spillage.

- Worn or Damaged Buckets

Old or broken buckets fail to hold and release material efficiently.

- Overloading

Excess feed overwhelms the buckets, leading to backflow.

- Poorly Adjusted Belt Tension

Loose belts can cause misalignment and premature discharge.

How to Prevent Excess Material Return

- Maintain optimal bucket speed for your material type.

- Regularly inspect and replace worn buckets.

- Ensure feed rate matches elevator capacity.

- Adjust belt tension to manufacturer recommendations.

-

Use material flow control devices to regulate feeding.

Industries That Rely on Bucket Elevators

- Cement Plants

- Grain Mills

- Food & Beverage Processing

- Fertilizer Manufacturing

-

Mining & Aggregates

Why Choose Neo Conveyors for Bucket Elevator Solutions - At Neo Conveyors, we design custom bucket elevators that minimize throwback, maximize efficiency, and deliver long-term reliability.

- Contact us today to optimize your material handling:

📞 +91-9654112235 | 📧 sales@neoconveyors.com