How To Keep Your Conveyor Running

How to Keep Your Conveyor Running Smoothly | Neo Conveyors

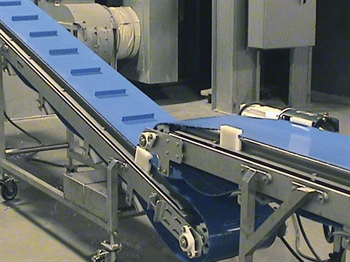

Keeping your conveyor system in peak condition is essential for uninterrupted production, fewer breakdowns, and longer equipment life. Whether you operate in manufacturing, food processing, FMCG, warehouse logistics, or automobile industries, proper conveyor maintenance can save time and costs.

1. Regular Inspection & Monitoring

Schedule routine checks to spot wear and tear early. Focus on:

- Belt tension and alignment

- Rollers and bearings condition

- Motor performance and gearbox health

-

Frame and structure stability

2. Keep Your Conveyor Clean - Dust, debris, and product residue can cause blockages or misalignment. Clean:

- Belts or chains after each shift

- Drive pulleys and tensioners

-

Under-belt areas where materials collect

3. Lubricate Moving Parts - Use manufacturer-recommended lubricants for:

- Bearings

- Chains

-

Gearboxes

This reduces friction and prevents overheating.

4. Train Your Operators - Improper operation causes most conveyor failures.

- Train staff to: Load materials evenly

- Avoid overloading

-

Stop machines before clearing jams

5. Use Genuine Spare Parts - Counterfeit or low-quality parts can shorten equipment life. Choose OEM parts from trusted conveyor manufacturers like Neo Conveyors for guaranteed compatibility.

Industries That Benefit from Proper Conveyor - Maintenance Plastic jar manufacturing

- Plastic household products

- Food products manufacturing

- Automobile assembly plants

- Warehousing & logistics

-

FMCG distribution centers

Why Choose Neo Conveyors? With over 18 years of experience in material handling and automation, Neo Conveyors offers custom-designed, high-performance conveyors built to last. -

📞 Call: +91-9654112235

📧 Email: sales@neoconveyors.com

🌐 Website: www.neoconveyors.com

To know more about conveyors, belt and conveyor systems, log on to http://www.bulkmaterialshandling.in