Picking the right Conveyor system for Your Business

Picking the Right Conveyor System for Your Business

Why Choosing the Right Conveyor System Matters

In today’s competitive industrial landscape, efficiency is everything. From food processing plants to automobile assembly lines, the right conveyor system ensures seamless material handling, faster operations, and reduced downtime. At Neo Conveyors, we specialize in designing and manufacturing tailored conveyor solutions that boost productivity across industries like packaging, warehousing, logistics, and plastic manufacturing.

Factors to Consider Before Choosing a Conveyor

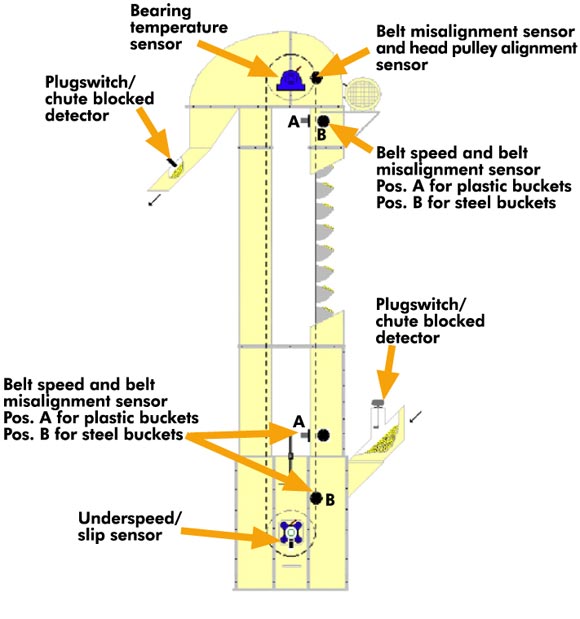

1. Type of Material to Handle Bulk materials like grains, cement, or powders require screw conveyors or bucket elevators. Unit loads such as boxes, cartons, and jars work best with belt conveyors or roller conveyors.

2. Space and Layout Limited floor space? Go vertical with spiral conveyors or vertical chain conveyors. Need flexible movement? Telescopic or flexible roller conveyors can save time in loading/unloading.

3. Industry-Specific Needs Food & beverages → hygienic, easy-to-clean conveyors. Automotive & heavy industries → robust chain or slat conveyors. Warehousing & logistics → automated belt conveyors for faster throughput.

Benefits of Choosing Neo Conveyors

- Customized design to suit your process and layout.

- Durable materials & components ensuring long life.

- Energy-efficient & cost-effective solutions.

- Wide product range: belt conveyors, screw conveyors, bucket elevators, drag chain conveyors, roller conveyors, and more.

Final Thoughts

Picking the right conveyor is not just about moving materials—it’s about optimizing efficiency, safety, and ROI. At Neo Conveyors, we partner with industries to design solutions that fit your exact needs, whether you’re in food production, packaging, warehousing, or heavy manufacturing.

👉 Visit www.neoconveyors.com today or contact our team to explore the best conveyor system for your business.