Working Principle of the bucket elevators

Bucket elevators: These elevators are utilized to transfer the granular material vertically. The fundamental parts of the gadget are an endless belt or chain as a footing component to which are connected a progression of conveying buckets

A solitary or twofold packaging, which serves to encase or incompletely encase the moving buckets. Ahead at the upper finish of the elevator which incorporates a belt pulley or chain wheel to turn the footing component and an appropriate release chute…

A boot at the lower end again incorporates a belt pulley or chain wheel, a tensioning gadget, and methods for taking care of the material to be passed on to guarantee ideal filling.

Types of bucket elevator

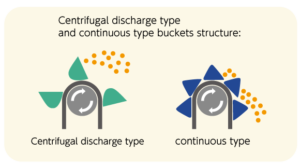

Difference between a centrifugal and continuous bucket elevator

Continuous bucket elevators are utilized for less vigorous bulk material taking care of uses. The moderate speed of this lift type evades the tossing activity related to centrifugal style elevators. Continuous elevators are then ideal for delicate materials, or materials that are inclined to air circulation.

Here’s the manner by which they work: the material is taken care of into the buckets from a gulf chute. The material at that point delicately spills out of the bucket and slides down the modified bucket and into the release chute.

Centrifugal bucket elevators are ideal when a lot of material should be moved rapidly. They are regularly chosen for taking care of strong and grating materials, for example, rock, woodchips, and sand.

Here are the means by which they work: Buckets scoop material up from the boot or delta segments. Centrifugal power at the head pulley “throws” material from the buckets and into the release chute.

Do you need a bucket elevator?

Neo conveyors are a manufacturer of bucket elevators in India since 2007. Please do contact us for any requirements of custom made bucket elevator.