Conveyor frameworks appear to keep the world’s enterprises moving. Since the mid-1900s and the beginning of large scale manufacturing on a scale never observed, particularly with the car business, these frameworks have been a standard sight in industrial facilities and sequential construction systems.

Conveyor frameworks appear to keep the world’s enterprises moving. Since the mid-1900s and the beginning of large scale manufacturing on a scale never observed, particularly with the car business, these frameworks have been a standard sight in industrial facilities and sequential construction systems.

It used to be that so as to create mass amounts of anything (recall the first plants in England and the United States) it required mass measures of individuals. The formation of passing on frameworks, notwithstanding, cut back on the measure of representatives required to carry out the responsibility and really expanded the measure of items that could be made at once. Rather than numerous hands to carry out the responsibility, it became numerous conveyors.

Similarly, the same number of enterprises utilize these frameworks, there is similarly the same number of alternatives for kinds of conveyor frameworks. These and more fill different needs and are found in businesses no matter how you look at it – car, food handling, materials, total. And so on, they use conveyor frameworks.

While a significant number of these alternatives require an engine to keep the line moving, one assortment utilizes a fundamental guideline of material science – gravity. The gravity conveyor is one of the more low-fi conveyor frameworks however is as yet utilized copiously in numerous organizations.

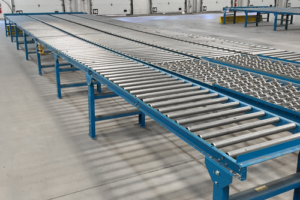

What is a gravity taken care of conveyor? This conveyor comprises a progression of skate wheels or rollers appended to a metal casing. They might be straight or bend around. You’ll discover gravity conveyors now and then in gear getting territories at air terminals, in supermarket checkout lines, and different spots.

Since it’s not mechanized, these took care of conveyors either should be on a slope to send items down the line, or they need a push to get them from A to B. Regardless of this, even enormous partnerships utilize gravity conveyors. Pressing and dispersion focus is a genuine case of gravity passing on frameworks in real life.

Such focuses may have systems of this kind of conveyor, some on slants, others level. They may not work for all creation settings, yet they are a more affordable conveyor framework will at present set aside an organization’s cash on work.

Gravity types on the head of being more affordable passing on frameworks are additionally very adaptable and helpful for some applications. A gravity roller conveyor works for heavier items and is frequently found in transportation and getting applications. Skate wheel conveyors are suggested for littler parts or sacks as they may slip between rollers.

An infeed framework can shoot materials or parts onto the gravity conveyor to utilize normal laws of gravity, particularly if the conveyor is on a grade. Gravity took care of conveyors and is additionally the main kind of conveyor framework that takes into consideration amassing. In the event that that is an essential part of your industry, at that point gravity conveyors are your framework.

Gravity took care of conveyors that have a long history and notwithstanding being quite low-tech are shockingly basic in the present businesses. From short lines to confusing systems, gravity conveyors discover applications in a combination of organizations. Perhaps a gravity conveyor framework is the one for you.

Peruse progressively about Gravity took care of conveyors