Types of a problem in bucket elevator

Types of a problem in bucket elevator

- Discharge – Down-legging – Back-legging

- Bucket Filling – Uneven Fill – Incomplete Fill

- Premature Bucket Failure •Wear •Cracking

Discharge Back-legging

- Back-legging depicts raised material tumbling down the up leg. – Causes

- Speed excessively quick

- Buckets worn

- Obstruction in head or throat

- Pressure vent or inward structure

Shroud in Head Helps control material stream and lessen release issues

Discharge Down-legging

- Down-legging depicts raised material tumbling down the down leg. – Causes

- Speed excessively quick/slow

- Wiper harmed or missing

- Throat position excessively high

- Buckets un-vented

- Obstruction in Throat

- High dampness/Sticky Material

- Air Pressure in Leg

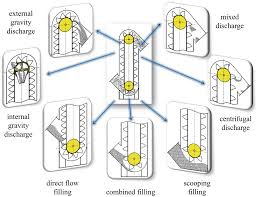

Bucket Discharge

- where the material begins to leave the pail is controlled by the belt speed, and the item being passed on.

- A rapid lift will start to release at around 30-40 degrees before top perfectly focused

- Complete release ought to happen at roughly 100 degrees beneath top perfectly focused

Discharge Position

- As rates and limits have gone up, throat position has gone down

- Most producers have a base situation of 45̊below centerline of the head shaft

Bucket Discharge

- In principle, the limit can be picked up by speeding up.

- Practical application can be dubious

Speed Increase Effects

- Earlier Discharge

- Higher toss direction

- Increased air volume

- Reduction of the time window

- Increase in ware harm

Bucket Fill Problems – Causes

- Misguided channel

- Buckets un-vented

- Pulley/channel position not ideal

- Speed excessively quick

- Vertical dividing

- Inlet modest

- Buckets worn

- Air Pressure in Leg

- Obstruction

Upside Feed Optimal Pulley Position

To Vent or Not to Vent

- Conveying dinners or delicate stock materials

- Sticky or high-fat substance

- Any light test weight materials

- Powders or flours

- WHEN IN DOUBT, VENT YOUR BUCKETS!

PREMATURE BUCKET FAILURE

- Causes – Improper equipment choice – Over-forced equipment – Incorrect basin or belt size – Misaligned belt – Excessive burrowing – Poor review rehearses –

- Solutions – Must introduce a locking gadget – Use appropriate force settings – Ensure pails and belting are legitimate widths – Install digger basins – Regular reviews to supplant harmed containers

Excessive Bucket Wear

- Misguided or helpless taking care of – Buckets must burrow to fill – Material over-burdening one side causing misalignment

- Improper can Material • Application will in general cake or develop in trunking

- Severe down legging causing substantial burrowing

Do you need a bucket elevator?

Neo conveyors are a manufacturer of bucket elevators since 2007. Please do contact us for any requirements.

Must Read: Different Ways of material discharging by Bucket Elevator