Bucket Elevators

One of the most proficient approaches to lift bulk materials vertically is with a bucket elevator. A Bucket Elevator comprises of a progression of buckets connected to a belt or chain with pulleys or sprockets situated at the top and lower part of the unit. The buckets are situated in a packaging or lodging to contain the material. Bulk materials are stacked into each bucket as the bucket moves past a gulf point. Neo conveyors manufacturer bucket elevators based on the characteristics of the bulk material and the process requirements.

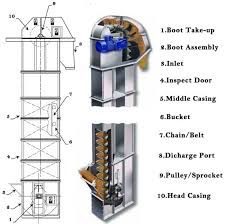

Bucket elevator Parts

ELEVATOR HEAD

- planned with replaceable wear plates

- conveyed with an effective empty shaft-mounted rigging with the standard engine and consolidated screen gadget to forestall invert development if there should arise an occurrence of unintended stops

- the outlet is tunable permitting release in either 45° or vertical down

ELEVATOR LEGS

- handily collected by methods for unique gathering clips and separation pieces, bringing about a durable development

- conveyed with a separable entryway in full length for administration and assessment and simple establishment of the belt and buckets.

- accessible in standard lengths – the specific stature is effortlessly accomplished by methods for the tallness modification area

ELEVATOR BOOT

- complete with gulf container that fits the extraordinary framework

- conveyed with an electronic speed watch that switches off the current if the belt begins to slip

- worked in cleaning entryway

- planned with belt tensioning gadgets effectively available on head of the elevator boot

- planned with a delegated pressure pulley to guarantee a straight running belt

ELEVATOR BUCKETS

- accessible in steel, hardened steel, and plastic

- put with a separation that guarantees a productive filling of the buckets and ideal treatment of the material at a high cap

DUST ASPIRATION

- connector for dust goal for association with focal extraction framework

- alternatively, can the elevator be ready for association with spot channel

ELEVATOR BELT

- Available in numerous kinds and characteristics.

- Antistatic as standard.

- oil-and fat safe as discretionary

- food grade as discretionary

- dimensioned with the rigidity of multiple times the ostensible working burden

ACCESSORIES AND FEATURES

- belt misalignment locator

- low-speed watch

- Rubber Lagging on the drive pulley

- desire associations

- top stage single or twofold sided Different Bucket And Casing Sizes Available For Capacities Up To 15,000 Cubic Feet Per Hour

Advantages of Using Bucket Elevators

- Designed To Handle A Wide Variety Of Bulk Materials – From Average To Very Free-Flowing

- Many Different Bucket and Casing Sizes

- Completely Enclosed For Dust and Weather-Tight Operation

- Inlet Section Can Be Control Fed or Flood Loaded With Bulk Materials of Using Bucket Elevators

- closed For Dust and Weather-Tight Operation

- Inlet Section Can Be Control Fed Or Flood Loaded With Bulk Materials

Must Read: Different Ways of material discharging by Bucket Elevator